Please wait, loading...

Please wait, loading...

![]()

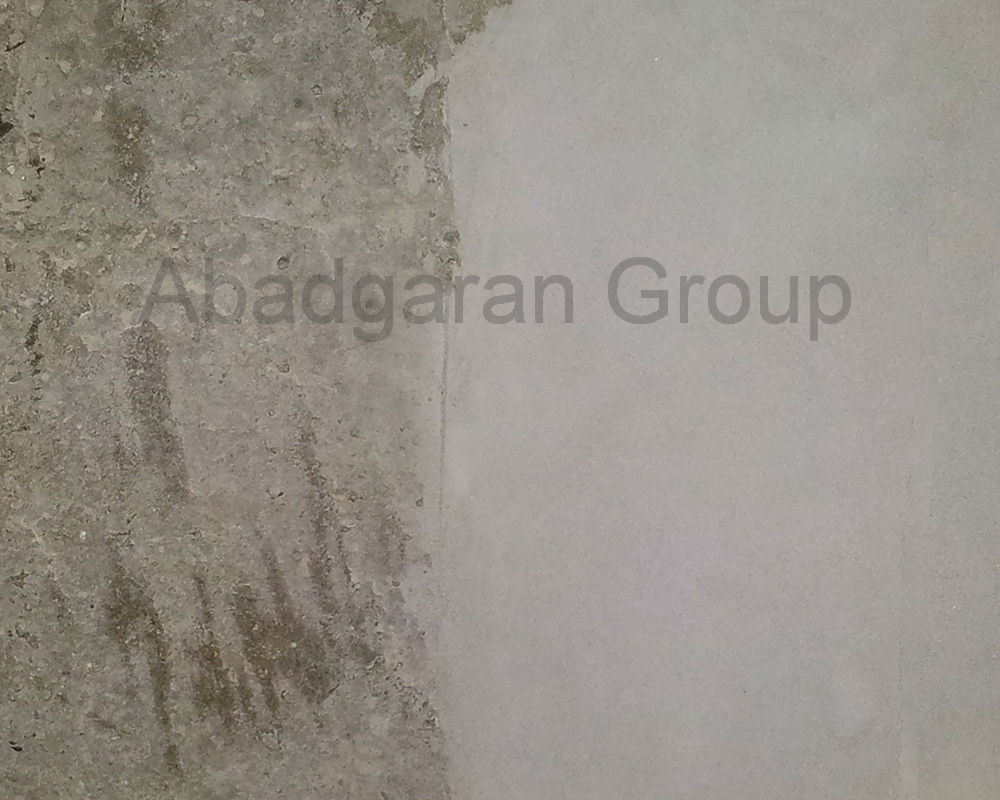

POLYMER MODIFIED SMOOTH CONCRETE REPAIR MORTAR

DESCRIPTION

SMOOTHER is a polymer modified cementitious one part repair mortar thin fairing coat for concrete surface small repairs.

It is made from especially selected, very fine fillers and additives to provide superior finishing.

And due to good adhesion and filling ability, it makes thin fairing coat before placement of special covering materials.

DOSAGE

The optimum dosage of SMOOTHER to meet specific requirement depending on porosity and

rough substrate, the normal dosage range is from 0.7 to 1.0 kg/m2 per 0.5 mm thickness of layer.

SUBSTRATE PREPARATION

Substrates should be clean sound and free from oil, grease, laitance and loose particles.

Metal surfaces should also be clean and free of rust, oil, grease and contaminants.

Thoroughly clean repair area using high pressure water jet to remove all loose debris and contamination.

The concrete should be presaturated for preferably 6 hours with water before application.

MIXING

SMOOTHER is simply mixed with water to yield a stiff easily workable compound with shrinkage compensating properties.

The quantity of water depends on the desired consistency but as a guide, we recommended,

the entire contents of the bag should be added to the pre-measured (8.7 liters approximately) water while mixing.

Mix with a paddle mixer or trowel to ensure a homogenous lump free material is achieved. Mix

for approx. 3 minutes. Do not try to remix the product after losing workability by the addition of more water.

APPLICATION

Apply SMOOTHER with a trowel or spatula. Press hard by hand. Thicker repairs may be achieved by working in layers. Build up in layers if necessary.

CURING

Keep repaired areas damp, with spraying water at least 24 hours.

ADVANTAGES

FIELD OF APPLICATION

|

Physical state |

Powder |

|

Color |

Gray |

|

Specific gravity of fresh mortar |

~1.6 g/cm³ |

|

Chloride ion |

Nil |

|

Pot life |

20 minutes @ +25°C |

STORAGE

HEALTH AND SAFETY

This product does not contain any substances hazardous to human health and the environment.

However, it should not be swallowed and allowed to be contact with skin and eyes. In case of contact with eyes,

rinse immediately with plenty of water. When applying gloves & goggles should be worn. SMOOTHER is not flammable.

For further information refer to the material safety data sheet.

MSDS is available at ABADGARAN website.