Please wait, loading...

Please wait, loading...

![]()

Research and Development Unit of Abadgaran Company

The Research and Development Unit of Abadgaran Chemical Industries is the beating heart of innovation in this organization. This unit consists of a team of experienced and creative specialists responsible for enhancing knowledge, developing new materials and methods, and solving existing challenges in the construction chemicals industry.

The introduction of the Research and Development Unit begins with a slogan that clearly expresses its nature. The slogan of the R&D Unit of Abadgaran Construction Chemical Industries is based on "New Ideas, New Solutions."

At the R&D Unit of Abadgaran Construction Chemical Industries, focusing on research and innovation, we are committed to creating sustainable, durable, and environmentally friendly products to build a brighter future for chemical technologies in various industries including construction, oil, healthcare, and more.

At the R&D Unit of the company, we are always seeking new and creative ideas. Using modern research methods and relying on our commitment and expertise, we aim to create an environment for the exchange of knowledge and ideas and the development of innovative materials that best meet customer needs.

The key activities of the R&D Unit of Abadgaran Construction Chemical Industries are as follows:

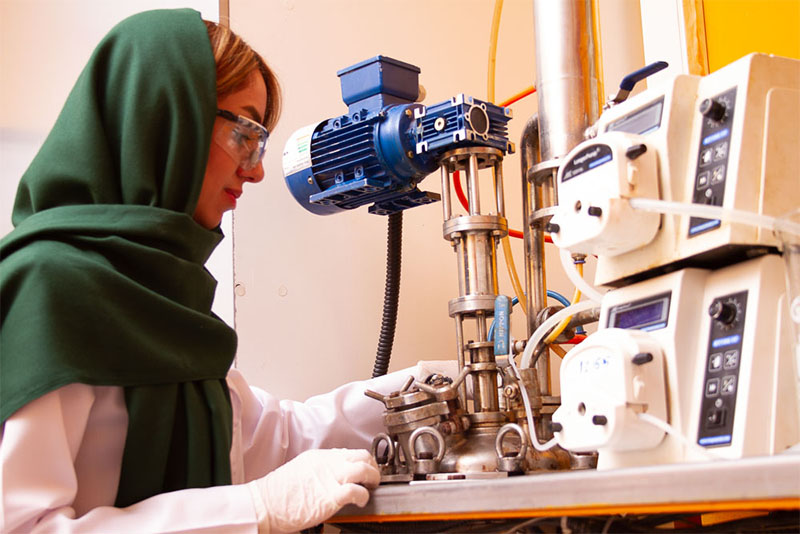

The research group at Abadgaran Construction Chemical Industries, as a pioneer in Iran's construction chemical materials industry, is always focused on developing and offering new and high-quality products and has also expanded into other fields beyond construction chemicals.

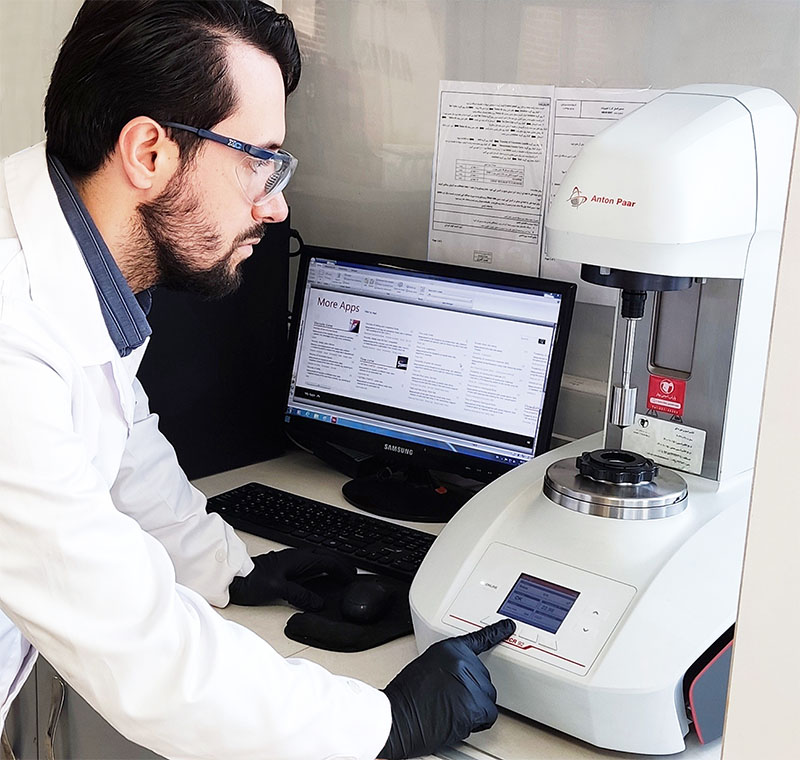

The research process begins in the laboratory and is a multi-stage process requiring careful planning, organization, and systematic execution.

In the first stage, efforts are made to design raw materials that not only address the company's internal and national needs, reducing dependency on imported materials, but also enhance the quality of produced goods. Each chemical product is carefully monitored at every stage to ensure its final quality. The materials designed and produced at this stage include:

Hi-tech or strategic materials of Abadgaran Construction Chemical Industries, which are mainly polymer-based. These materials are either sold as final products or used as raw materials for producing other chemical products, such as various grades of plasticizers including polycarboxylates, naphthalenes, lignosulfonates, and plant-based materials.

The second group includes hardeners or curing agents, mainly amine-based or phenolic-based, used with resins for various coatings and flooring applications.

The third group includes materials whose importation has been restricted due to sanctions, and the Abadgaran research group is working towards self-sufficiency in producing them, such as defoamers, designed in both water-based and solvent-based grades.

After the initial design, the practical application phase of the material in the final product begins. In this stage, considering the specific features tailored to the required properties, the material is evaluated in various formulations. Special characteristics considered include resin and hardener curing at low temperatures, performance under high humidity, maintaining efficiency under harsh temperatures, corrosion resistance, and more.

The practical application of produced materials begins according to the following steps:

All epoxy and polyurethane base paints applicable on concrete, metal, etc.