Please wait, loading...

Please wait, loading...

![]()

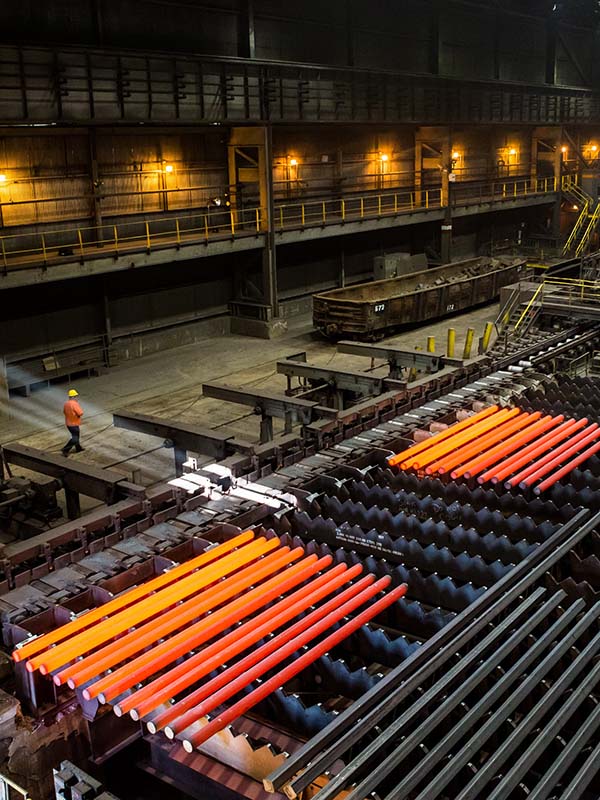

ABAGROUT-HR200

ABAGROUT-HR200 PREPACKAGED NON-SHRINK HEAT RESISTANT CEMENTITIOUS GROUT

ABAGROUT-HR200 is a non-shrink and highly flowable cementitious ready-mix mortar with significant performance in facing high temperatures. This specially formulated material with 5mm maximum aggregate size, can obtain high mechanical properties, therefore it is the best choice for installation of base plates of heavy machineries which will face variable high temperatures up to 300 ºC. It is recommended to apply ABAGROUT-HR200 up to 100 mm. It can be checked for requirements of the following standards:

ASTM C1107, EN 1504

SURFACE PREPARATION

Surfaces should be clean sound and free from oil, grease, laitance and loose particles. Metal surfaces should also be clean and free of rust, oil, grease and contaminants.

The prepared areas should be flooded with water prior to the placement of ABAGROUT-HR200 before the grout is placed. All free water should be released from the area to be grouted. There should be NO standing water present when the grout is placed.

MIXING

ABAGROUT-HR200 should be mixed using a suitable mixer. For flowable consistency use a band drill and paddle with a speed of <400 R.P.M. For large works use a high shear vane grout mixer. (Drum mixers are not recommended).

The entire contents of the bag should be added to the pre-measured (2.250-3.000 liters) water while mixing. It is recommended to use minimum water that is enough for achieving flowable mixture and should prevent from adding extra water.

DO NOT add more than the maximum water content.

APPLICATION

Ensure the substrate is prepared according to the manufactures recommendations.

Grouted free surface should be limited to 10cm. It is recommended to prevent grouting when weather is windy and also prevent from direct sunshine.

NO free water should be present in the area to be grouted. Ensure that there are sufficient air release holes for entrained air to escape.

Mortar should be continuously poured, from one side only, until the gap is completely filled. Maintain continuous head of grout when pouring.

CURING

It is necessary to cure exposed areas of grout with humidified method for at least 7 days.

|

Cementitious powder |

Physical state |

|

Gray |

Color |

|

2.40 ± 0.1 g/cm³ |

Specific gravity of fresh grout |

|

9 – 12 % |

Water by weight of grout |

|

None |

Chloride content |

|

Approximately 45 minutes(depend on weather and temperature) |

Workability |

|

~ 30 MPa |

Compressive strength -1 day |

|

~ 55 MPa |

Compressive strength -3 days |

|

~ 65 MPa |

Compressive strength -7 days |

|

~ 85 MPa |

Compressive strength -28 days |

|

~ 12 MPa |

Flexural Strength -7 days |

|

~ 15 MPa |

Flexural Strength -28 days |

|

5 mm |

Max Aggregate Size |

This product does not contain any substances hazardous to human health and the environment. However, it should not be swallowed and contact with skin and eyes. In case of contact with eyes, rinse immediately with plenty of water. ABAGROUT-HR200 is not flammable.

For further information refer to the material safety data sheet. MSDS is available at ABADGARAN website.